zavolat na :

+86 18681515767

zavolat na :

+86 18681515767

e-mailem :

marketing@jtspeedwork.com

e-mailem :

marketing@jtspeedwork.com

zavolat na :

+86 18681515767

zavolat na :

+86 18681515767

e-mailem :

marketing@jtspeedwork.com

e-mailem :

marketing@jtspeedwork.com

01. naše výrobky

horké výrobkyShenzhen Jietong Technology Co., Ltd. je technologicky vyspělá společnost zaměřená na vývoj, výrobu a prodej radiofrekvenční identifikace (rfid).

vždy o krok víc!

Shenzhen Jietong technology Co., Ltd je high-tech společnost zaměřená na výzkum a vývoj, výrobu a prodej UHF RFID hardwaru. Jietong má vlastní tým pro výzkum a vývoj, jehož inženýři mají více než 10 let zkušeností v oblasti výzkumu a vývoje. Aby bylo možné poskytovat zákazníkům ty nejlepší služby a produkty, společnost Jietong se neustále vyvíjí, aby nabídla celé řešení projektu, poprodejní servis a technologickou podporu. Jietong má hlavní produktové řady, které zahrnují čtečku UHF RFID Impinj R2000/TM200 pro čtení více značek , čtečku UHF RFID pro čtení jedné značky , čtečku UHF RFID s dlouhým dosahem , čtečku UHF RFID středního dosahu , UHF RFID stolní čtečku/zapisovačku , modul čtečky UHF RFID , UHF RFID ruční čtečka , UHF RFID anténa , UHF RFID karta a štítek atd., Jietong má zásadu nadřazenosti uživatelů a závisí na tržně orientované, nové technologii a vysoké kvalitě, poskytneme nejnovější technologii, nejlepší produkty, konkurenceschopné, upřímně služby našim klientům. Prosadili jsme se jako spolehlivá, inovativní a důvěryhodná součást podniků jejích zákazníků a dodavatelů.

02. proč nás vybrat

naše výhodaShenzhen Jietong Technology Co. ltd., je technologicky vyspělá společnost zaměřená na výzkum a vývoj, výrobu a prodej radiofrekvenční identifikace (rfid). speciální profesionál v čtečce řady věcí uhf rfid internetu věcí. jietong má vlastní tým výzkumu a vývoje, jehož inženýři mají více než 10 let zkušeností s výzkumem a vývojem. za účelem poskytování nejlepších služeb a produktů zákazníkům je společnost jietong neustále ve vývoji, aby nabídla celé řešení projektu, poprodejní servis a technologickou podporu.jietong má hlavní produktové řady, které zahrnují modul rfid uhf, ruční čtečku rfid, čtečku rfid uhf, čtečku rfid pro parkování ve středním dosahu, čtečku řízení přístupu uhf, anténu uhf, karty a značky uhf atd.,čtečka jt uhf rfid, která se již intenzivně používá ve správě vozidel, s využitím prostředí zahrnuje také správu zaměstnanců pro továrnu, správu hmotnosti pro sklad, kontrolu přístupu do skladu a vozidla, správu oděvů, správu logistiky tabáku, inteligentní správu knihoven, správu identifikace výrobní linky, aktiva management atd.,jietong má princip nadřazenosti uživatelů a závisí na tržně orientované, nové technologii a vysoké kvalitě, našim klientům poskytneme nejnovější technologii, nejlepší produkty, konkurenceschopnost a upřímný servis.

profesionální

profesionální

tým výzkumu a vývoje má více než 10 let zkušeností;

produkt

produkt

nabízet levný, střední a vysoce kvalitní produkt;

kvalitní

kvalitní

národní patentová ochrana pro produkt vlastní značky

servis

servis

2 roky záruka a 3 roky údržba nákladů;

03. projektové případy

ŘEŠENÍ & PŘÍPADTato stránka řešení pomáhá zákazníkům vyřešit problém instalace a správy aplikací pomocí produktů Jietong Technology. Jsou zahrnuty následující: Správa vozidel Správa osobního systému UHF Řízení výrobní linky Logistické vedení Správa majetku Správa skladu Ekologická hygiena vozidel řídí Inteligentní správa knihovny

RFID Technology in the Renewable Energy Sector: Applications and Opportunities 1. Introduction As the global renewable energy industry expands, efficient asset management, supply c...

Přečtěte si více

správa vozidels terapeutickým rozvojem čínské ekonomiky se zvyšuje životní úroveň lidí; také rychle začalo růst celkové vlastnictví automobilu. v současné době jsou problémy ve spr...

Přečtěte si více

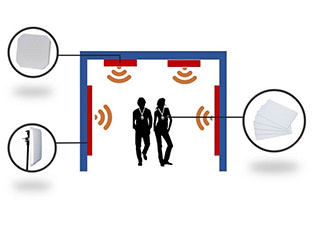

uhf rfid systém personálního managementu>> přehled systémusystém řízení zaměstnanců na dlouhé vzdálenosti je moderní systém řízení zaměstnanců kombinující technologii uhf rfid, int...

Přečtěte si více

řízení výrobní linkyza účelem výroby kvalitnějších produktů při současném snížení výrobních nákladů a splnění požadavků normy iso9000 výrobci lépe sledují informace o produktu a ko...

Přečtěte si více

řízení navádění kolejí na kolech AGVs úrovní výroby a zvyšující se poptávkou zákazníků čelí řada logistických systémů mnoha výzvám, například jak zlepšit efektivitu obratu logistic...

Přečtěte si více

systém pro správu RFID aktivpřehled systémuzpůsob, jak ručně implementovat správu aktiv, včetně zvýšení, distribuce, skladování, likvidace atd., již nikdy nemůže uspokojit znovu po...

Přečtěte si více

04. Události

poslední zprávyShenzhen Jietong Technology Co., Ltd. je technologicky vyspělá společnost zaměřená na vývoj, výrobu a prodej radiofrekvenční identifikace (rfid).

05. konzultace zdarma

zanechat vzkazpokud vás zajímají naše produkty a chcete vědět více podrobností, zanechte zde prosím zprávu, my vám co nejdříve odpovíme.

telefon : +86 18681515767

Whatsapp : +8618681515767

e-mailem : marketing@jtspeedwork.com

12/F, Building A, No. 6, Shiben Road, Shiyan Street, Bao'an District, Shenzhen, Guangdong, China-518108

autorská práva © 2026 Shenzhen Jietong Technology Co.,Ltd. všechna práva vyhrazena.

Síť ipv6 je podporována